Detailed Picking/Packing/Shipping Workflow

Description

The ICXE manages Order Fulfillment accuracy by requiring line items to be checked while orders are packed. By scanning stock barcodes or by manual inspection incorrect items, missed items, under or over counts are quickly detected.

Detail Steps

Pick - This step picks the inventory from the location.

Pack - This step packs the inventory to be despatched.

Ship - This step despatches the inventory by using one of the available shipping methods.

ICXE supports LIFO, FIFO, MIN, MAX, LEXFO, FEXFO picking strategies as standard.

- LIFO means Last In First Out, so stock most recently received will be selected for picking, FIFO selects oldest stock first.

- MIN looks for small quantity batches of stock, MAX large quantities of stock.

To Pick an Order;

- Click the checkout item from the Despatch Register.

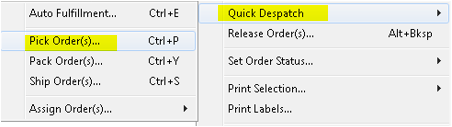

- Go to Actions → Quick Despatch → Pick Orders… or press Crtl+P.

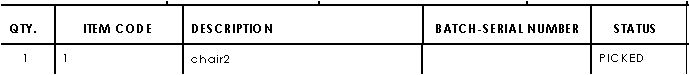

- The status of the despatch record will be changed to PICKED.

Note that only NSA (No Stock Available), CROSS DOCK or RTP despatch records can be picked.

Once stock has been Picked it is placed ON HOLD by the ICXE.

At this point the warehouse manager will generally select the “Pick Slip” option to print our a Pick Slip that will be used as a guide to retrieve stock from the warehouse and the identified Bins.

The Pick Instructions will identify each stock item along with batch-serial-lot numbers and location information.

Once the stock has been picked, it will be displayed as below.

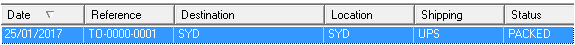

Packing an Order

To pack an order that has been picked in the previous step;

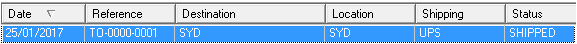

Recording a Shipped Order

Note: Choose which reports are to be printed when confirming shipping.

Once the order is shipped, the status and manifests are updated.

Related Information

None

Need Assistance?

Call 1800 137 032 Email support@datapel.com